2022 High quality solder paste stencil machine - JUKI SMT RS-1R pick and place machine fast Smart Modular Mounter – Chengyuan Detail:

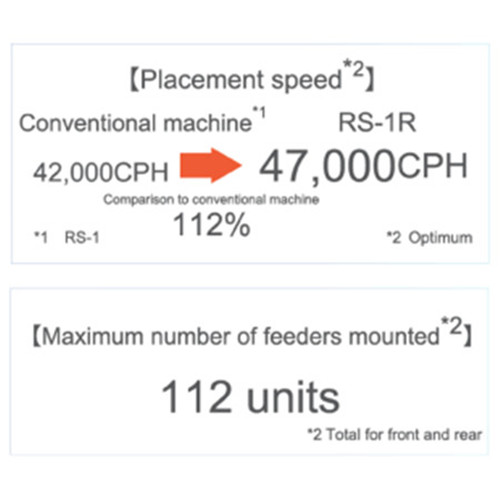

Class leading speed, up to 47,000 cph

Maximum speed of up to 47,000 cph*.

This is made possible by a revolutionary head design that reduces the travel time and distance for every placement.

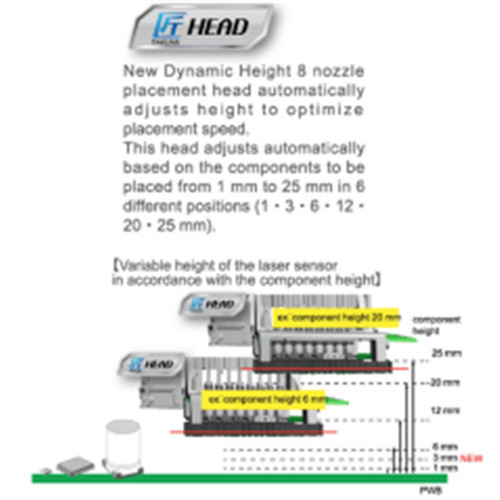

Self-Optimizing Smart Head

“Takumi head” that automatically optimizes it’s height between 6 different positions based on component height. Tact time is

optimized by keeping the head as close to the PCB as possible for the components placed.

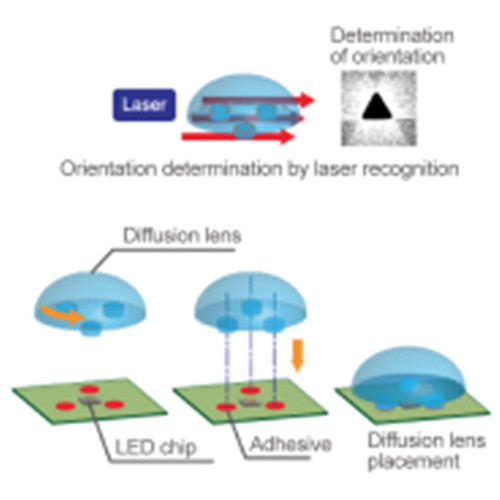

Optimal for LED placement

● High-precision placement of diffusion lenses. RS-1R can use either vision or laser centering for diffusing lenses, depending on the component requirements. A wide range of lens styles can be placed.Up to 650 x 370mm with single clamping. LED chip Conveyor direction 2nd clamp placement area

● Long PCB Support Up to 950 x 370mm with dual clamping, or up to 1200 x 370mm with optional conveyor extensions.

Specifications:

Fast Smart Modular Mounter

| Model | RS-1R | ||||

| Conveyor specification | standard | 150mm conveyor extensions, upstream and downstream |

250mm conveyor extensions, upstream and downstream |

||

| Board size | minimum | 50×50㎜ | |||

| maximum | 1buffer | 650×370 ㎜ (Single clamping) | |||

| 950×370 ㎜ (double clamping) | 1,100×370 ㎜ (double clamping) | 1,200×370 ㎜ (double clamping) | |||

| 3buffers | 360×370㎜ | 500×370㎜ | 600×370㎜ | ||

| Component height | 25㎜ | ||||

| Component size | 0201*1 ~□74 ㎜ /150×50 ㎜ | ||||

| Placement speed | Optimum | 47,000CPH | |||

| IPC9850 | 31,000CPH | ||||

| Placement accuracy | ±35μm(Cpk≧1) | ||||

| Vision recognition | ±30μm | ||||

| Feeder inputs | max.112*2 | ||||

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for 2022 High quality solder paste stencil machine - JUKI SMT RS-1R pick and place machine fast Smart Modular Mounter – Chengyuan , The product will supply to all over the world, such as: Colombia, Rotterdam, Malta, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!