2022 wholesale price SMT Stencil - GKG GSE SMT Stencil Printer – Chengyuan Detail:

1. The GKG dedicated manual adjustment jacking platform is simple, reliable, low-cost, and easy to adjust manually. It can quickly adjust the height of the PIN pin top of different thickness PCB boards.

2. Image and optical system New optical system – uniform ring light and high-brightness coaxial light, with brightness function that can be infinitely adjusted, making all types of Mark points can be well recognized (including uneven Mark Point) to adapt to tin, copper, gold, spray tin, FPC and other types of different colors of PCB.

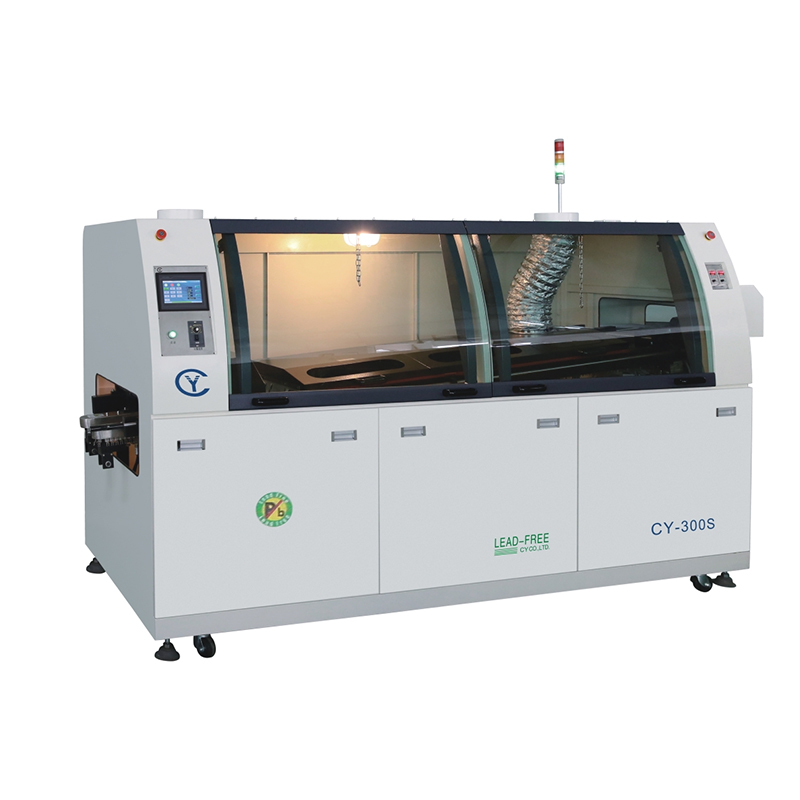

3. Scraper system slide-type scraper system to improve operating stability and prolong service life.

4. Cleaning System The new wiper strip ensures full contact with the stencil, and the large vacuum suction force guarantees that the solder paste remaining in the cell hole can be eliminated. The effective automatic cleaning function is achieved: three cleaning modes of wet and dry vacuum, and the software is free to use Set the cleaning mode and cleaning paper length.

5. Steady steel net fixing structure

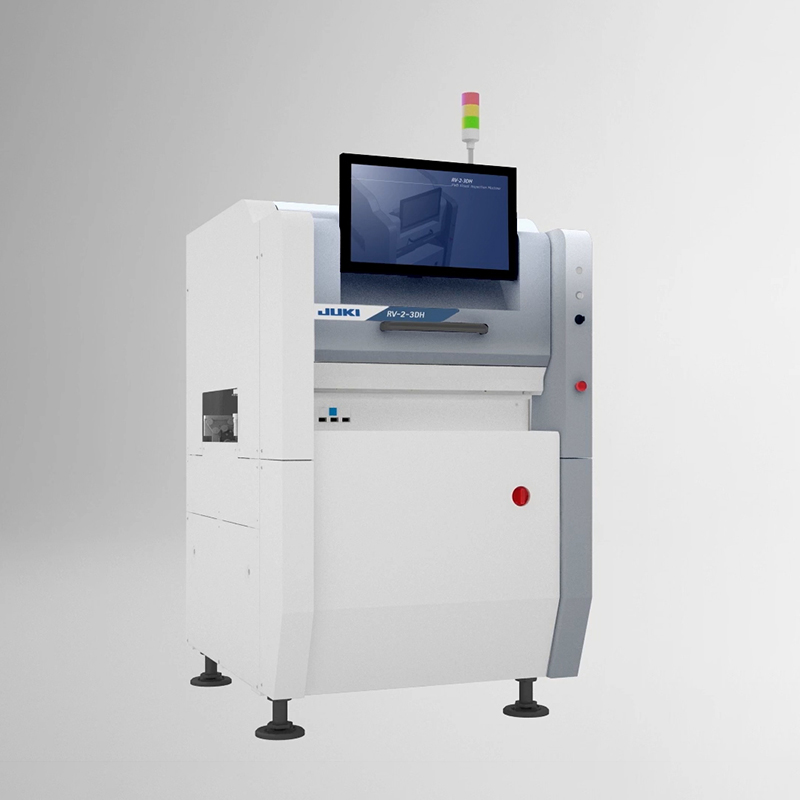

6. Perfect 2D detection system

Specifications:

| Item | Parameter | |

| Repeat Position Accuracy | ±0.01mm(Test data and method are available) | |

| Printing Accuracy | ±0.025mm(Test data and method are available) | |

| Printing Speed / Cycle Time | <8s (Exclude Printing & Cleaning) | |

| Products Changeover | <5Min | |

| Screen Stencil Size/Min-Max | 470mm X340mm-737x737mm | |

| Screen Stencil Size/Thickness | 20mm ~ 40mm | |

| PCB Size/Min-Max/Thickness | 80X50mm-400x340mm/0.4~15mm | |

| PCB Warpage Ratio | <1%(Based on diagonal length) | |

| Bottom of Board Size | 15mm(Standard configuration), 25mm | |

| Edge of Board Size | 3mm | |

| Conveyor Height | 900±40mm | |

| Conveyor Direction | Left-Right; Right-Left; Left-Left; Right-Right | |

| Conveyor Speed | 100-1500mm/sec Programmable control | |

| Board Positioning | Support System | Magnetic pin/Side support block/Flexible automatic pin(optional) |

| Clamping System | Elastic side clamping/Vacuum nozzle/Extension-type Z-direction table setting | |

| Print head | Two indepandent Motorised printheads | |

| Squeegee Speed | 6~300mm/sec | |

| Squeegee Pressure | 0-10kg software control(closed-loop pressure feedback), pressure value visible | |

| Squeegee Angle | 60°(Standard )/55°/45° | |

| Squeegee Type | Steel squeegee (standard), rubber squeegee, and other types of squeegee shall be customized. | |

| Steel Mesh Separation Speed | 0.1~20mm/sec Programmable Control | |

| Cleaning Method | Dry-type, wet-type, vacuum-type ( Programmable combination of Cleaning methods) | |

| Table Adjustment Range | X:±3mm; Y:±7mm θ:±2° | |

| Type of Fiducial Point | Standard geometry shape of fiducial point, bonding pad / Stencil hole | |

| Camera System | Single digital camera for upward/downward vision system | |

| Air Pressure | 4~6Kg/cm2 | |

| Air Consumption | Approx 0.07m3 /min | |

| Control Method | PC Control | |

| Power Supply | AC:220±10%,50/60HZ 1Φ 1.5KW | |

| Machine Dimensions/Weight | Depends on exactly model | |

| Operation Temperature | -20°C ~ +45°C | |

| Operation Humidity | 30%~60% | |

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for 2022 wholesale price SMT Stencil - GKG GSE SMT Stencil Printer – Chengyuan , The product will supply to all over the world, such as: Iceland, United Arab emirates, Ottawa, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.