The transmission mechanism adopts precise modular design, with accurate transmission, long service life and easy maintenance.

Automatic switch can be carried out according to the date, time and temperature control parameters set by the user

The closed loop automatic tracking and spraying system can automatically adjust the spray width and spray time, and can set early and delayed spray as required.

Automatic wave-lifting through plate, adjustable peak width of tin furnace, minimizing tin oxidation

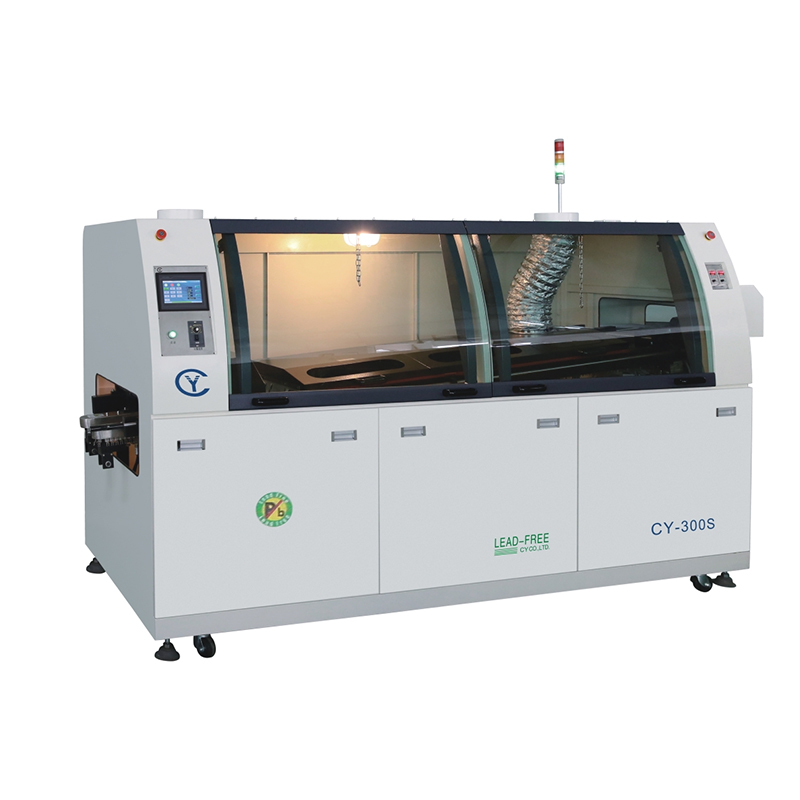

Technical parameters

| Model | CY-250 |

| Control mode | Touch screen + PLC |

| Transport motor | 1P AC220V 60W |

| PCB width | 50-250mm(w) |

| Preheating zone | Power: 6KW Length: (600mm section infrared preheating PID control) |

| Solder Box heating | 9KW (room temperature - 300 C) |

| Solder box capacity | 180Kg |

| Wave motor | 3P AC 220V 0.37KW*2pcs,Brand:Tai Chuang(Taiwan) |

| Pawl wash pump | 1P AC220V 6W |

| Cooling | Normal air cooling |

| PCB Transport Direction | L→R /(R→L) |

| Nozzle movement | Stepper motor |

| Scaling powder aaccccccwdasqcccapacity | 6 LITRES |

| Flux pressure | 3-5BAR |

| Welding angle | 4-7℃ |

| Power supply | 3P AC380V 50Hz |

| Total power/operating power | 18KW/4KW |

| Weight | 500KG |

| Body dimensions | 1800(L)x1200(W)x1650mm(H) |

| Exterior dimensions | 2500(L)x1200(W)x1700mm(H) |