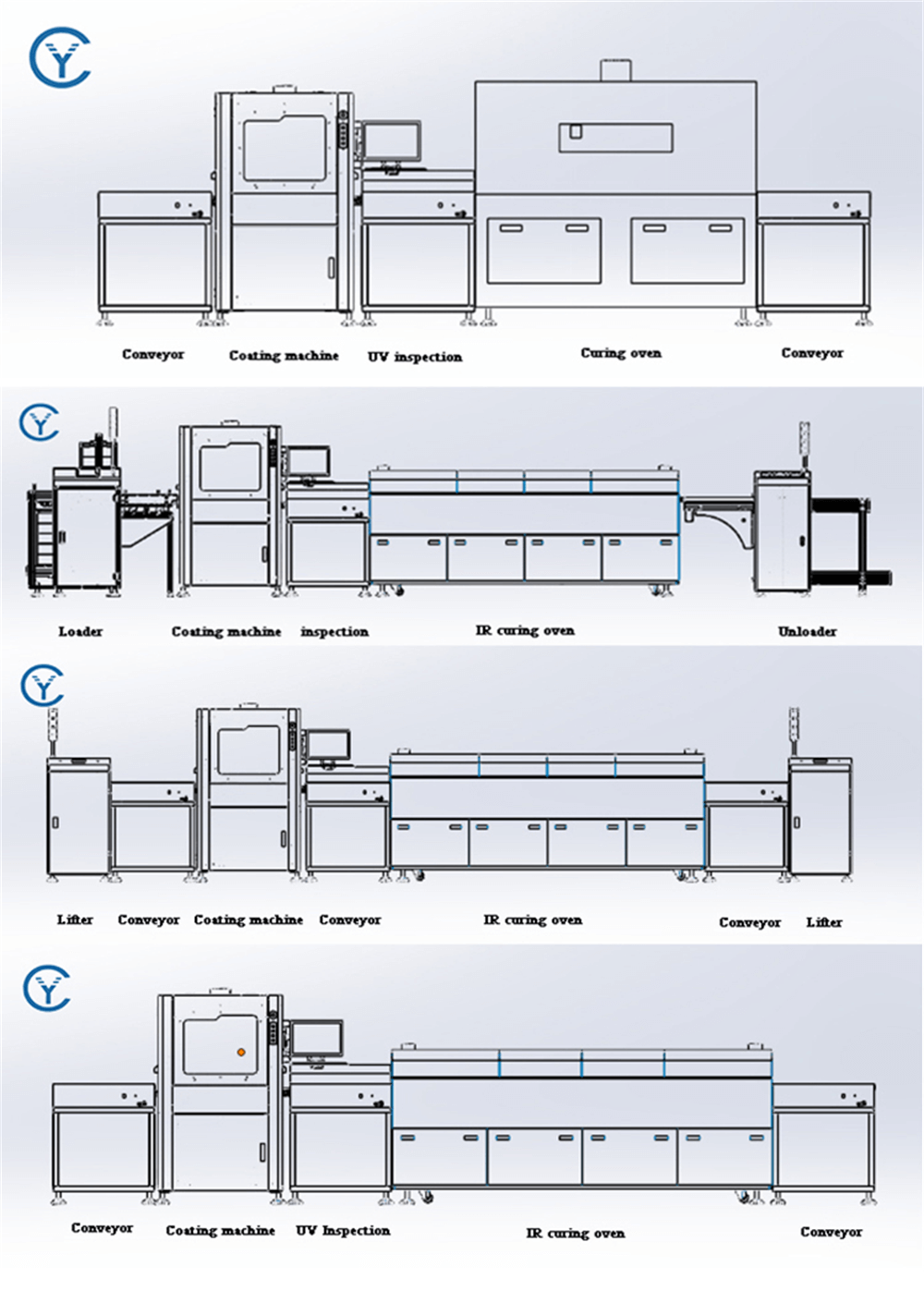

The CY-460F has many options and integrated features including:

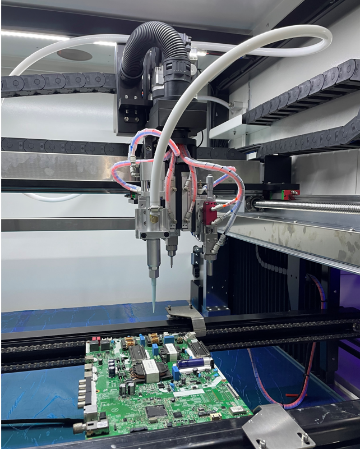

● Robotic system repeatability of 25 microns

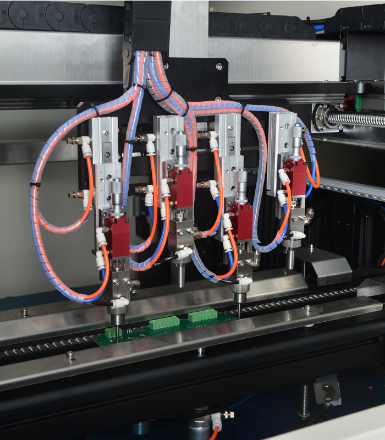

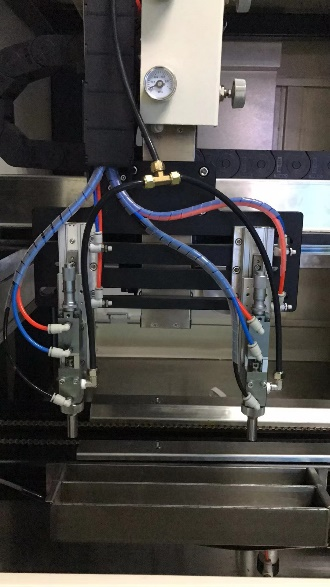

● Patented servo-controlled optional four-axis motion featuring valve tilt and rotate

● Closed loop process control throughout gantry system

● Multiple dispensing applications or materials in one cell

● Onboard PC for unlimited program storage

● Exclusive CY programming environment

Coating values

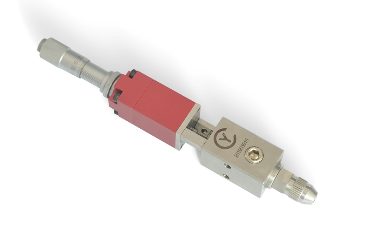

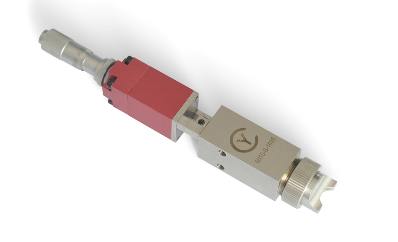

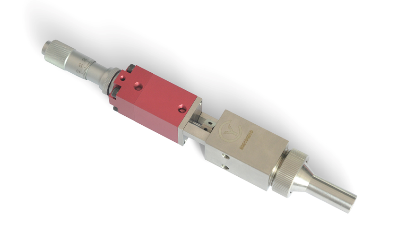

JC-200N- Needle atomizing valve

JC-200V- Thimble dispensing valve

JC-200B- Fan-shaped atomizing valve

JC-200M-Conical atomizing valve

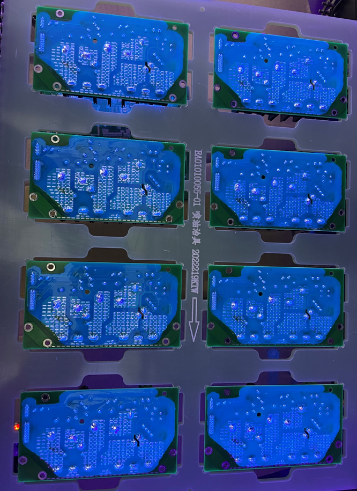

Coating results

Conformal coating solutions

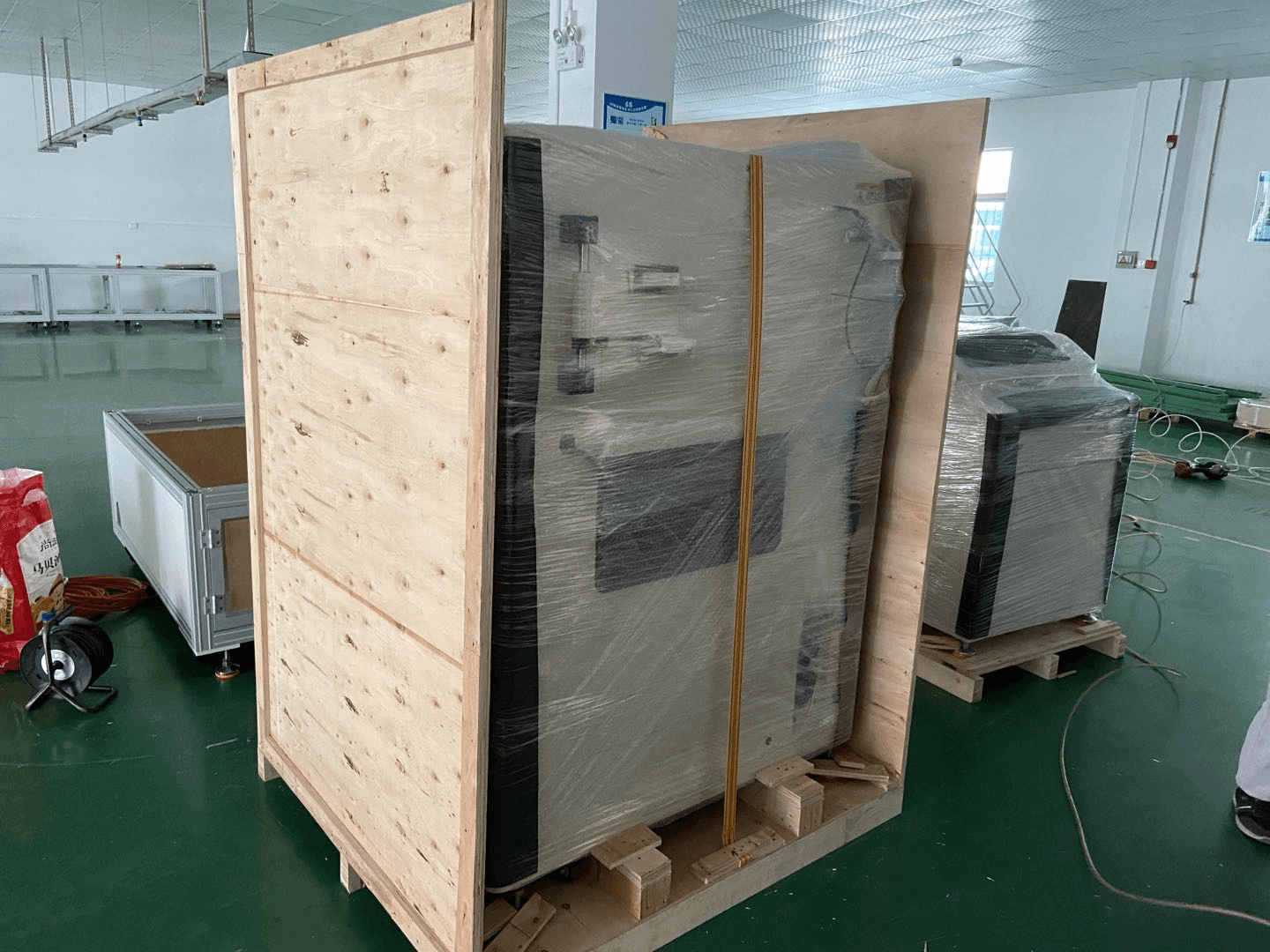

Packing

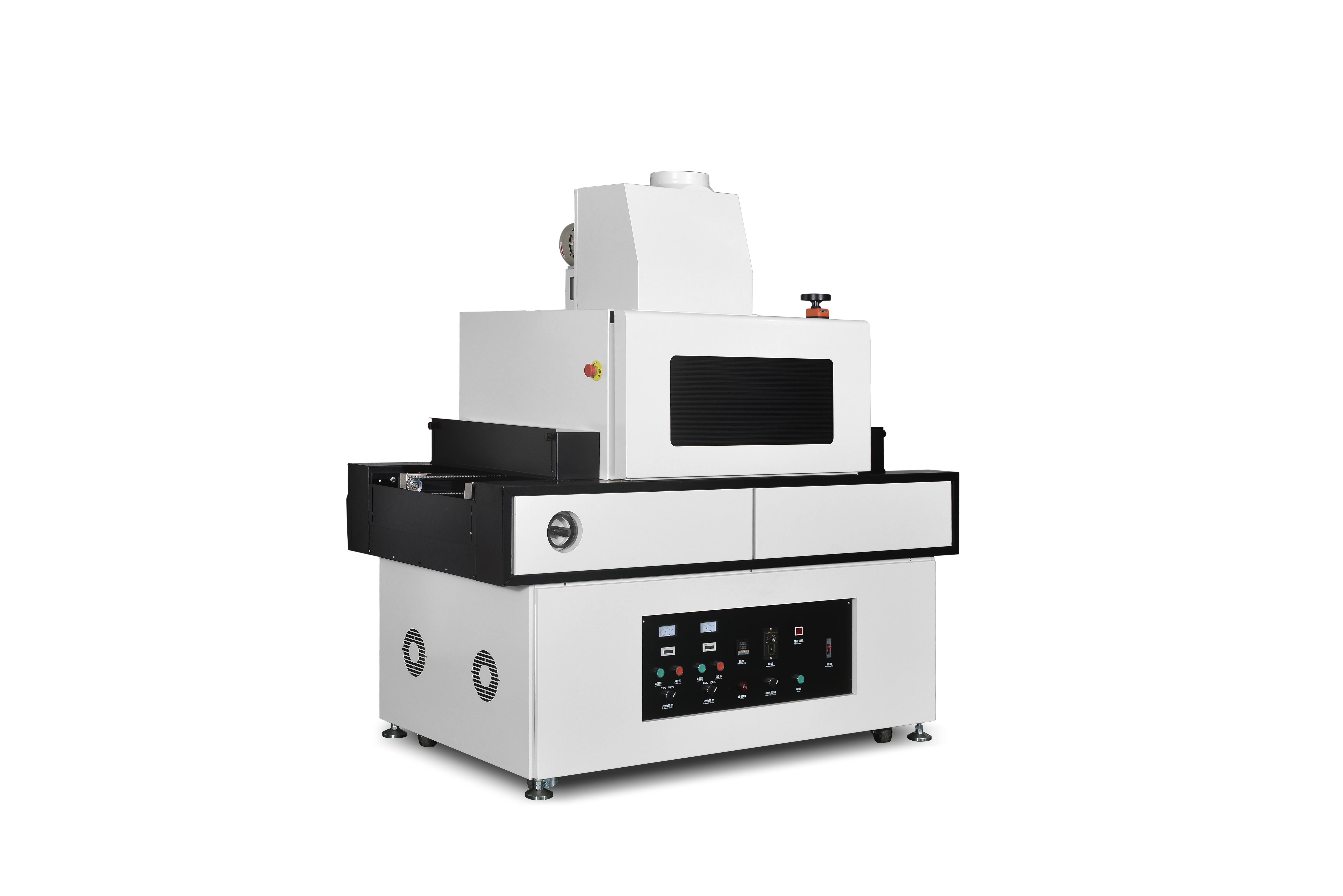

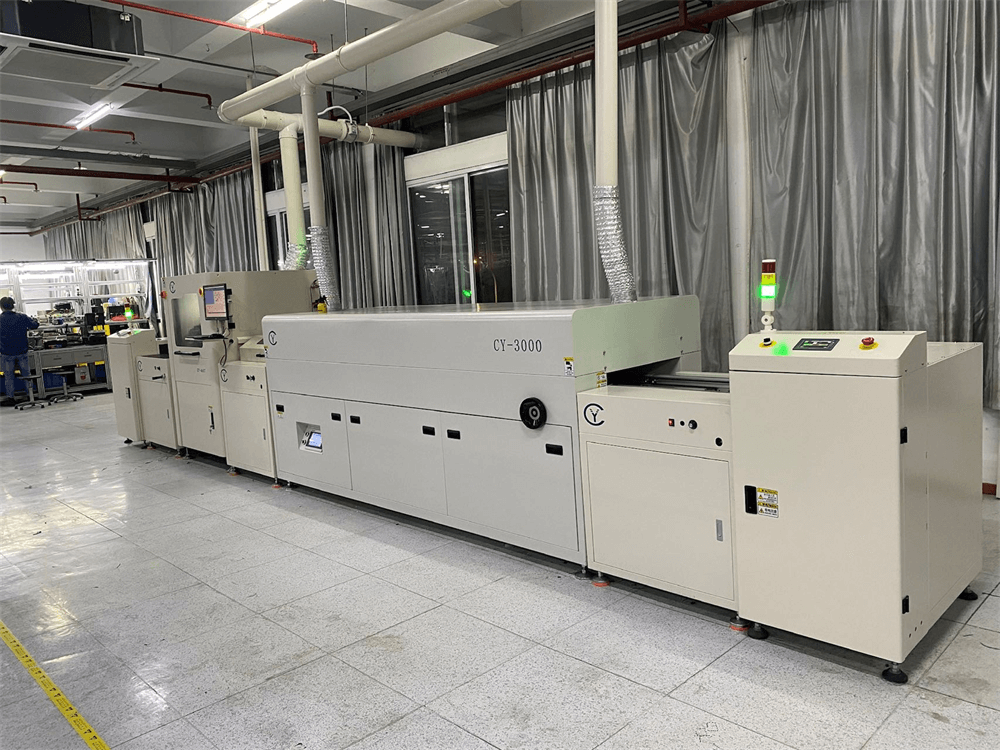

CY460F Equipment parameters (F series)

| Frame size | L1060mm*W1200mm*H1700mm |

| Weight | 760kg |

| Method of control | Industrial computer + motion control card |

| Programmatically | Manual teaching |

| Run the software | Chengyuan Coating Machine Intelligent Selective Control Software |

| PCB Transmission height | 900±20mm |

| Transportation speed | Max 300mm/s |

| Transmission direction | Left → right |

| transfer method | Stainless steel chain + stepper motor |

| PCB Width range | 50-450mm |

| Method of width | Stepping motor automatically adjusts the width |

| X、Y Shaft drive mode | Servo motor + high-precision screw module |

| X、Y Maximum operating speed of shaft | 1000mm/s |

| X.Y Axis positioning accuracy | 0.02 mm |

| Z Maximum operating speed of shaft | 500mm/s |

| Z Shaft drive | Servo motor + high-precision screw module |

| Z Axis positioning accuracy | 0.02 mm |

| Valve up and down | Slide cylinder |

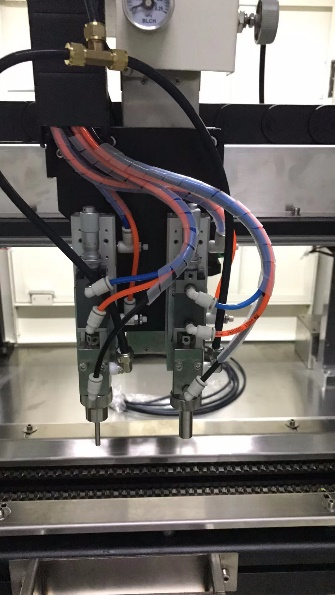

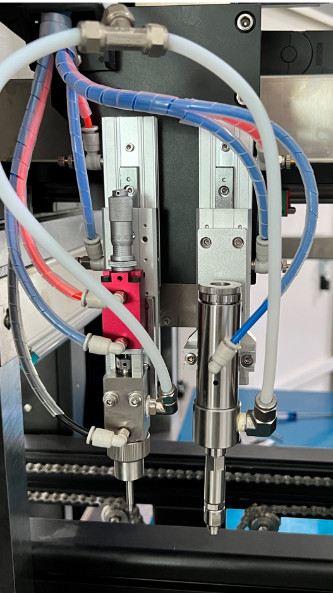

| Number of valves | 2 pcs |

| Valve type | Cone valve/needle atomization valve |

| PCB Board size | MAX W50mm*L460mm |

| PCB Board component height | MAX 100mm |

| Coating width | 1-30mm(According to the type of valve) |

| Tank volume | 10L Glue supply pressure tank |

| Cleaning bucket | 500mL |

| Cleaning function | The equipment comes with cleaning function |

| Lighting part | The equipment comes with white light and purple light |

| power supply | AC220V |

| Gas source | ≥0.4MP |

| Total power | 2.5KW |

| Automatic cleaning device | Standard |

| Barcode scanning function | Optional |

| CCD Visual positioning | Optional |