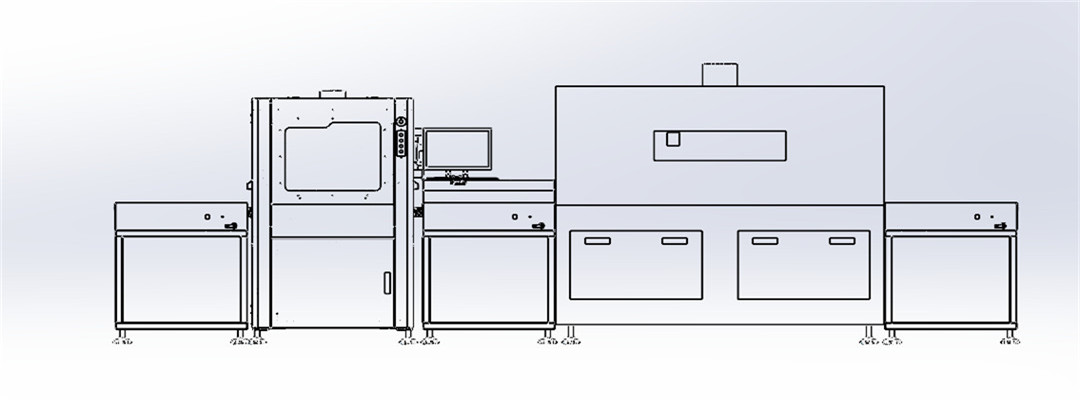

High Quality Selective Conformal Coating Machine – CY High Precision Selective PCBA Conformal Coating Line with IR /UV Curing Oven – Chengyuan Detail:

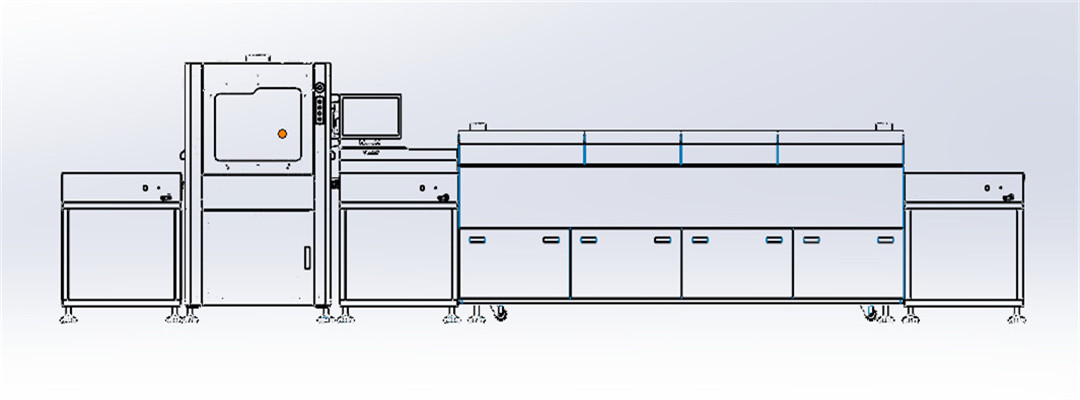

PCB conformal coating machine

The equipment adopts industrial computer control, windowssa7 operating system.

Driven by servo motor + ball screw, with automatic precision calibration function, which can automatically eliminate errors;

The equipment track automatic pressing function, the spraying accuracy is higher, the repeat accuracy is improved, the glue is isolated from contact with the transportation chain, and the maintenance cycle is reduced;

It can carry two or more sets of valve bodies at the same time to increase production capacity and realize splicing spraying;

Equipped with coating valve automatic soaking and automatic spitting device, which can avoid the clogging of the valve mouth, and the maintenance is convenient and quick;

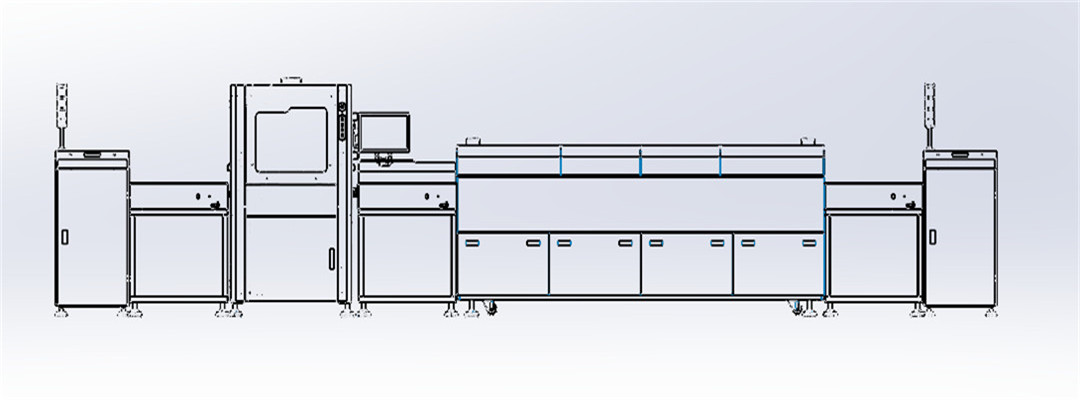

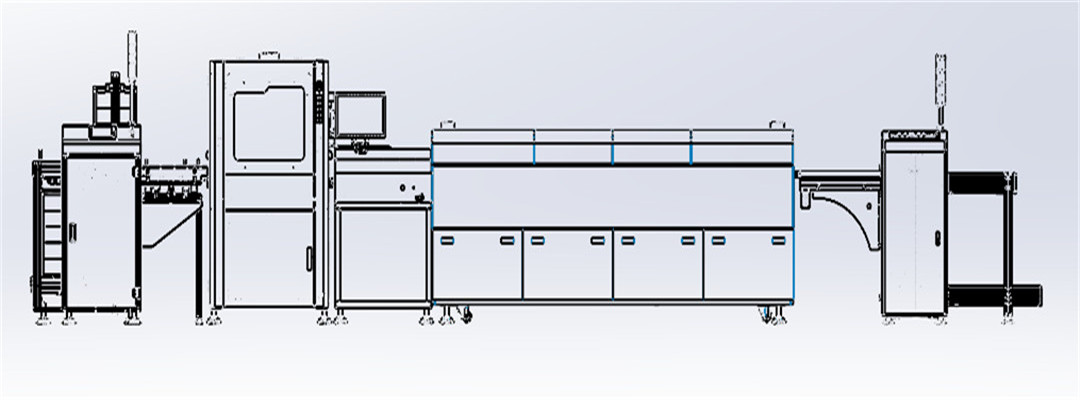

PCB Coating Loader &Unloader

PCB conformal coating line conveyor

1. Modular design, optional assembly as per client’s requirement.

2. Rugged steel design, improves equipment stability .

3. Smooth stainless steel screw to adjust the width of the rail.

4. Variable speed control.

5. Circuit board testing mode.

6. Using a dedicated aluminum slot for transfer orbit to prevent PCB stuck.

7. Heavier bottom design, not easily shift.

Conformal Coating line UV Curing Oven

1. Control system:Instrument or PLC+touch screen control, make sure machine working steadily.

2. UV lamp lifetime can reach 1000-1200 hour, the energy of UV is higher and the penetration ability of the coating is stronger. abnormal lamp protection device.

3. Conveyor belt made by Teflon materials, has no pole speed regulation, and speed is stable and adjustable.

4. Focus design, import high light reflector lamp shade, instant drying, fast speed..

5. Independent cooling area ensures the low temperature when PCB comes out.

6. Transmission system use imported motors, speed adjuster, smoothly running, adjustable speed at 0-2000mm/min.

7. Stainless steel chain transportation, the effective width is 50-450mm, the width can be adjusted.

Specifications:

| Frame size | L1060mm*W1200mm*H1700mm |

| Weight | 760kg |

| Method of control | Industrial computer + motion control card |

| Programmatically | Manual teaching |

| Run the software | Chengyuan Coating Machine Intelligent Selective Control Software |

| PCB Transmission height | 900±20mm |

| Transportation speed | Max 300mm/s |

| Transmission direction | Left → right |

| transfer method | Stainless steel chain + stepper motor |

| PCB Width range | 50-450mm |

| Method of width | Stepping motor automatically adjusts the width |

| X、Y Shaft drive mode | Servo motor + high-precision screw module |

| X、Y Maximum operating speed of shaft | 1000mm/s |

| X.Y Axis positioning accuracy | 0.02 mm |

| Z Maximum operating speed of shaft | 500mm/s |

| Z Shaft drive | Servo motor + high-precision screw module |

| Z Axis positioning accuracy | 0.02 mm |

| Valve up and down | Slide cylinder |

| Number of valves | 2 pcs |

| Valve type | Cone valve/needle atomization valve |

| PCB Board size | MAX W50mm*L460mm |

| PCB Board component height | MAX 100mm |

| Coating width | 1-30mm(According to the type of valve) |

| Tank volume | 10L Glue supply pressure tank |

| Cleaning bucket | 500mL |

| Cleaning function | The equipment comes with cleaning function |

| Lighting part | The equipment comes with white light and purple light |

| power supply | AC220V |

| Gas source | ≥0.4MP |

| Total power | 2.5KW |

| Automatic cleaning device | Standard |

| Barcode scanning function | Optional |

| CCD Visual positioning | Optional |

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for High Quality Selective Conformal Coating Machine – CY High Precision Selective PCBA Conformal Coating Line with IR /UV Curing Oven – Chengyuan , The product will supply to all over the world, such as: Argentina, Czech, French, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.