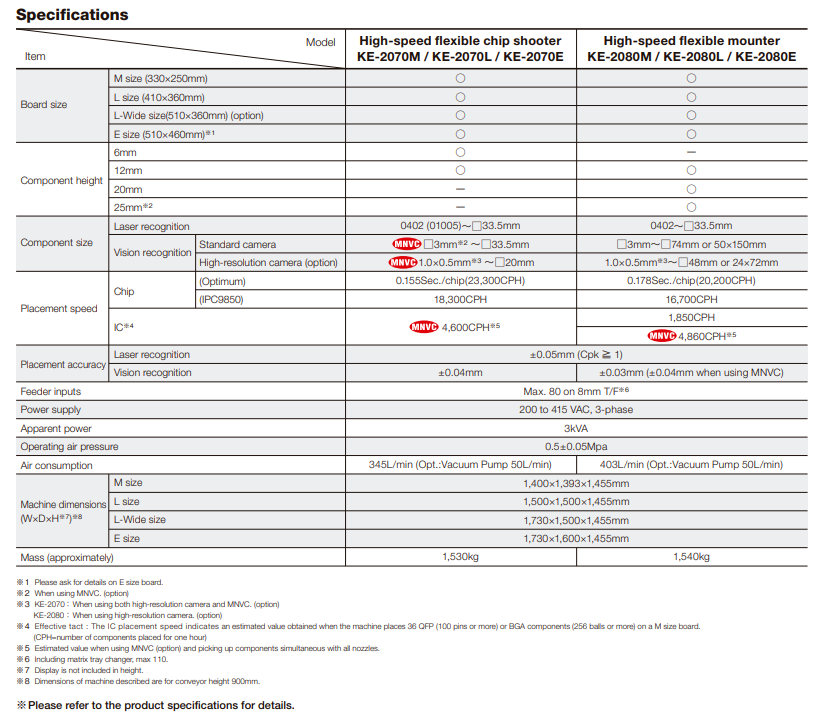

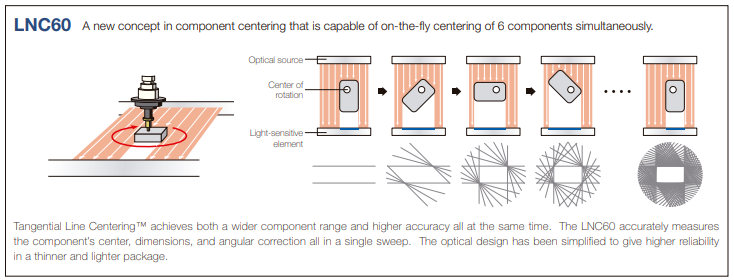

1 New laser sensor: LNC60

The new LNC60 laser head is capable of picking and centering 6 components simultaneously. It can reach speeds of up to 18,300 CPH (IPC-9850), a 23% improvement over the previous generation. A variety of different nozzles can be attached at the same time, decreasing the nozzle change time. With the optional MNVC (multi-nozzle vision centering), the throughput for high accuracy devices is increased a remarkable 40%. And all of these features are found in a remarkably compact machine for unparalleled productivity.

The LNC60 brings a new concept in laser centering to the market. This sensor has the unique ability to center components from 0402 (01005) to 33.5mm square parts. From ultra-small, ultra-thin, chip-shaped parts to small QFP, CSP, BGA, a wide range of parts can be mounted by the laser recognition system at high-speed and with high-accuracy.

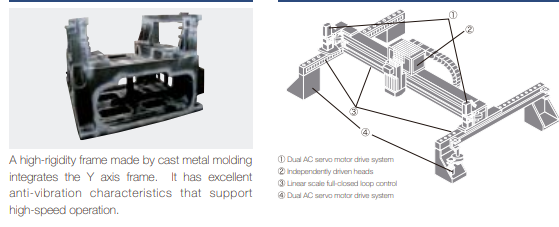

2 Dual XY drive system & independently driven heads

A high-rigidity frame made by cast metal molding integrates the Y axis frame. It has excellent anti-vibration characteristics that support high-speed operation

X-Y drive system features JUKI's original "Full closed loop control" using AC motors and magnetic linear encoders. Dual motor drive of both X and Y achieves high-speed, and highly reliable placements unaffected by dust and temperature variations. Independent Z and u motors improve accuracy and robustness

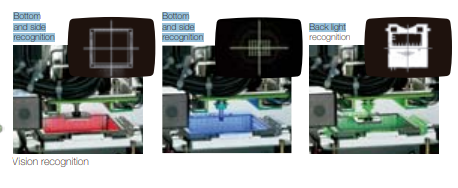

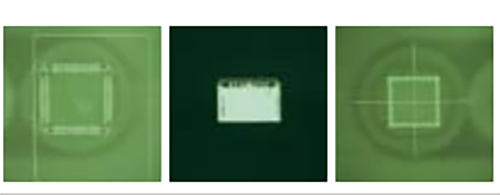

3 Vision centering technology

Centering method can be selected based on component type, shape, size and material. Laser centering is used for high speed placement of smaller components. Vision is used when lead or ball inspection is needed or when the component is too large for the laser. Many nozzles are available for odd-shaped components providing unsurpassed component handling.

(2)MNVC (Multi-Nozzle Vision Centering)

Vision centering by the multi-nozzle head nearly doubles the placement rate for smaller components, including CSPs, BGAs, and smaller QFPs. (Option) MNVC is also available on the KE-2070.

4 Advanced features for increasingly sophisticated and diversified applications

(1)FCS (Flex Calibration System

JUKI's highly regarded easy maintenance just got even easier! The optional FCS calibration jig is a simple to use system to re-calibrate placement accuracy. The machine automatically picks and places jig components, then measures the error and adjusts all necessary calibrations. (optional)

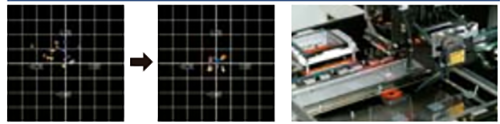

(2)Fiducial recognition

OCC lighting system supports wide variety of board materials including FPC (Flexible Printed Circuit board) Programmable brightness and directional lighting improves fiducial recognition.