Manufacturer of reflow equipment - Lead-free reflow soldering CY-A4082 – Chengyuan Detail:

5. The lower heating adopts “infrared +. Hot air” mode, which can effectively penetrate the PCB and heat the pad on the welding surface; At the same time, in order to prevent the non-uniform heating of pure infrared, the hot air circulation is increased. This not only enhances the heating capacity, but also ensures the PCB heating uniformity.

6. Segmented layered cooling system, up and down cooling mode, can effectively control the cooling rate, PCB outlet temperature is less than 50 degrees.

7. Synchronous rack and rail transmission mechanism to ensure the accurate width adjustment and high service life of guide rail.

8. The computer-controlled automatic lubrication system can automatically lubricate the transmission chain by setting the refueling time and refueling amount through the computer.

9. Integrated control window, computer switch, electric width adjustment, test curve, print curve and data transmission are easy to operate

10. Curve test and curve analysis function can analyze the maximum temperature, interval time, heating and cooling rate, which is convenient for process adjustment.

11. The operating system with password management can prevent irrelevant personnel from changing process parameters, and the operation recordmanagement can trace the change process of process parameters to facilitate the improvement of management.

12. Windows 7 Windows operation interface, Siemens PLC + LCD computer control system, with high security function

13. Rosin recovery system, rosin directional flow to the storage bottle, replacement and cleaning is very convenient. Stainless steel tube is used to transfer waste gas, life-long maintenance free.

14. The optional nitrogen distribution system and cooling system of chiller are available. When the nitrogen consumption is 20m3/h, the oxygen concentration in welding area is lower than 500ppm

Specifications:

| CY A series Reflow soldering technology parameters | ||

| Series | A series | |

| Model | CY-A4082 | CY-A40102 |

| The heating part parameters | ||

| Heating area | Up 8 /Down 8 | Up10/ Down 10 |

| Number of cooling zone | Top 2/ Bottom 2 or Top 3 /Bottom 3 | |

| Heating zone length | 2790 mm | 3107 mm |

| Transportation part parameters | ||

| PCB maximum width | 400mm | |

| Rail wide adjust range | 50-400mm | |

| Transport direction | L→R(R→L) | |

| Fixing method of transport guide rail | Front/back end | |

| Conveyor height | Belt 900±20mm,Chain 900±20mm | |

| Transmission way | Chain drive + Chain drive | |

| Conveyor speed | 300-2000mm/Min | |

| Control part parameters | ||

| The power supply | 3-phase 380V 50/60hz | |

| Start power | 38Kw | 58Kw |

| Normal work consumed power | Approx.7.5Kw | Approx.8.5Kw |

| Heating up time | About 15-20 minutes | |

| The temperature control range | Room temperature -300℃ | |

| Temperature control mode | Full computer PID closed loop control, SSR drive | |

| The whole machine control mode | Computer +PLC | |

| The temperature control precision | ±1℃ | |

| The deviation of PCB temperature distribution | ±1-2℃ | |

| Cooling way | Air machine: air cooling, nitrogen machine: water cooling | |

| Abnormal alarm | Abnormal temperature (ultra high or ultra low after constant temperature) | |

| Three color light | Yellow – temperature rise; Green – constant temperature; Red anomaly | |

| The body parameter | ||

| Weight | Approx.1700Kg | Approx.1900Kg |

| Installation dimensions(mm) | L5050×W1400×H1450 | L5750×W1400×H1450 |

| Exhaust air requirements | 10 cubic / min 2 channel ∮ 200mm | |

| Nitrogen part (optional) | ||

| Nitrogen protection device | Nitrogen flow 20-30 m3 / h, oxygen concentration 500-800ppm | |

| The external water cooling system | Power 3P refrigeration speed ≥ 6 ℃ / sec | |

Parts list

| Name | Brand/origin |

| PLC | Siemens/Germany |

| Control Computer | Dell/America |

| AC contactor | Chint/China |

| Disconnector | Chint/China |

| SSR | Cheng Yitai/Taiwan |

| Transducer | Asiantime/China |

| Intermediate relay | Omron/Japan |

| Relay | Omron/Japan |

| Insurance seat/ Fuse | Chint/China |

| Switching Mode Power Supply | Ming Wei/Taiwan |

| Three color model light | Ou En/China |

| UPS Power Supply | Santak/America |

| Optoelectronic switch | Cheng Yitai/Taiwan |

| Button switch | Cheng Yitai/Taiwan |

| Conveyor motor | Tai Chuang/Taiwan |

| Heating tube | Tai Zhan/Taiwan |

| Cylinder | AirTAC /Taiwan |

| Solenoid valve | AirTAC /Taiwan |

| Pressure regulating valve | AirTAC /Taiwan |

| Blower Motor | San Yue/Taiwan |

Attached parts list

| Item | Quantities |

| Tool case | 1 set |

| Allen wrench | 1 set |

| Monkey wrench | 1 set |

| Sharp-nose pliers | 1 set |

| Cross screwdriver | 1 set |

| Straight screwdriver | 1 set |

| SSR | 1 set |

| Octagonal relay | 2 pcs |

| Fuse | 2 pcs |

| Manual | 1 pcs |

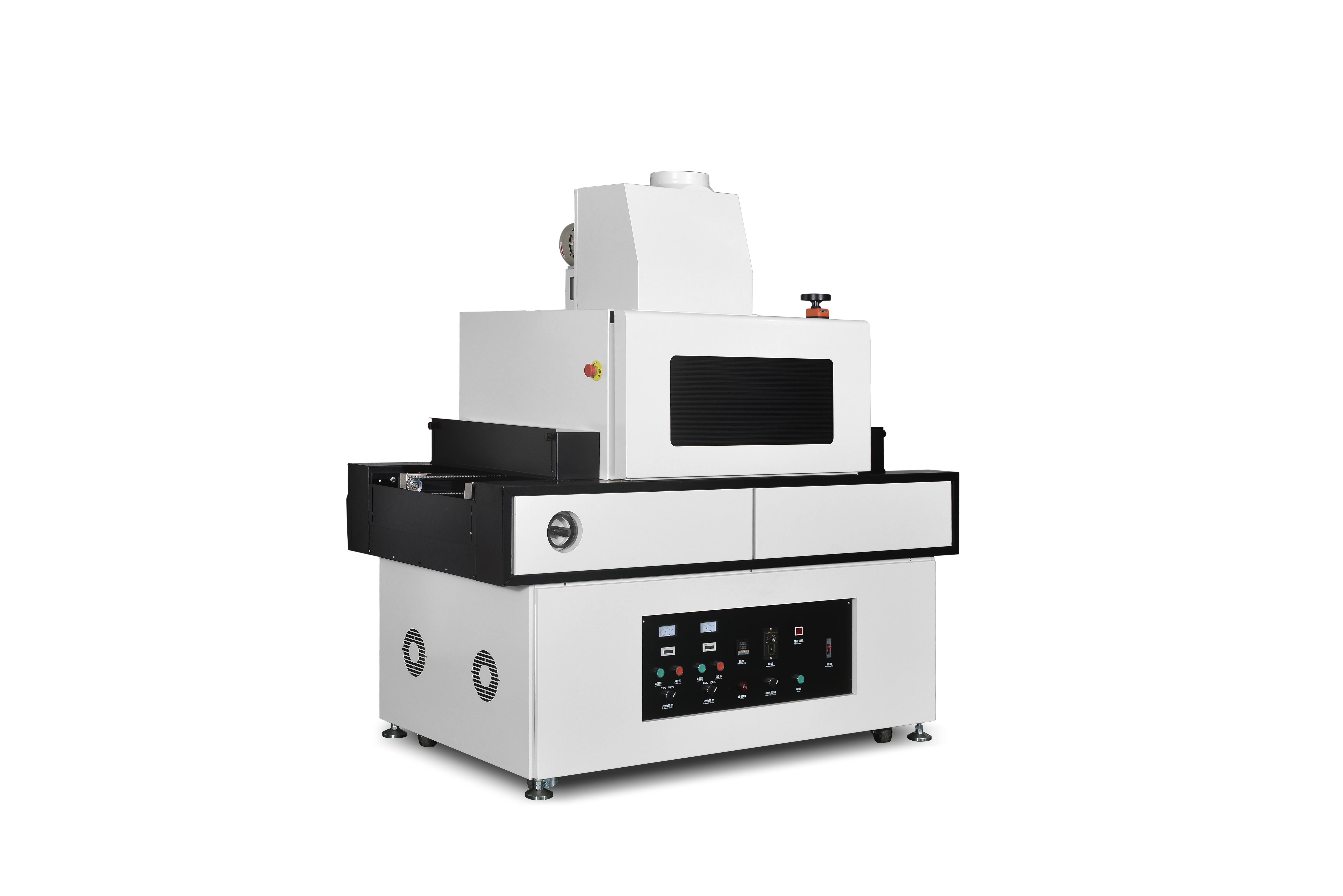

Product detail pictures:

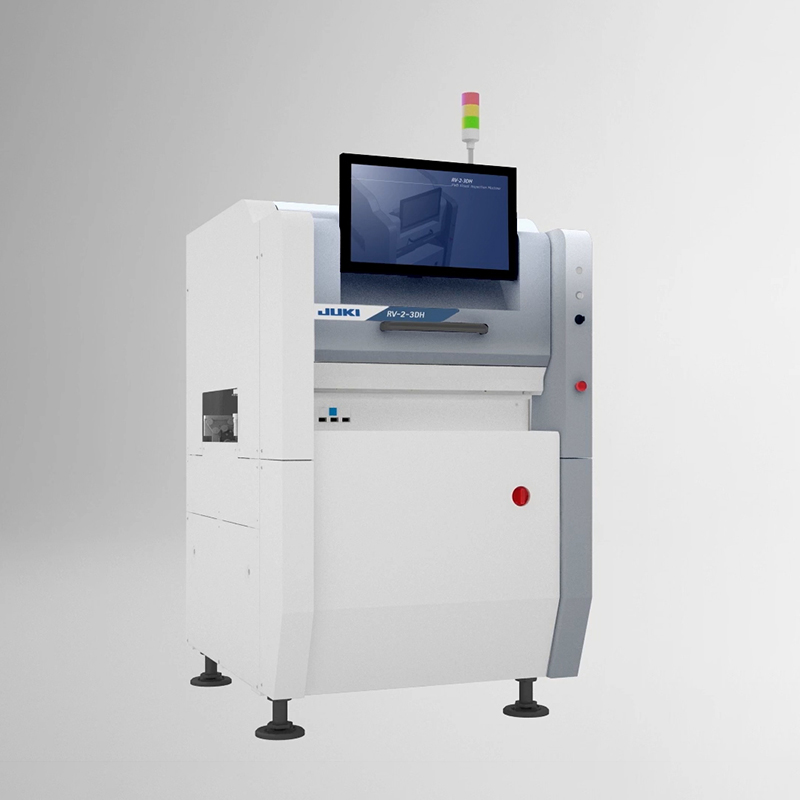

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Manufacturer of reflow equipment - Lead-free reflow soldering CY-A4082 – Chengyuan , The product will supply to all over the world, such as: Hyderabad, Honduras, Angola, What You Need Is What We Pursue.We are sure our products will bring you first class quality.And now sincerely hope to promote partner friendship with you from all over the world. Let's joint hands to cooperate with mutual benefits!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.