Professional China frameless stencil printer - Lead-free Wave Soldering machine CY-350B/350T – Chengyuan Detail:

6. The board is automatically waved, and the width of the tin furnace wave peak can be adjusted to minimize the amount of tin oxidation

7. 1800mm extended type three (four) stage preheating, infrared (hot air) independent PID temperature control, Even heating, safe and stable

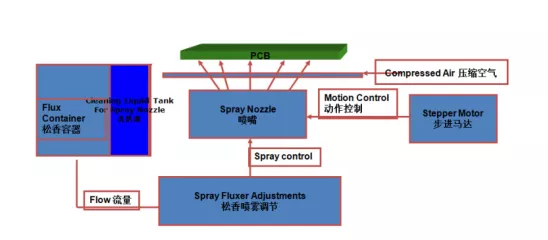

◆ With Lumina (Japan) nozzle, the spray range is20-65mm, the nozzle height is 50-80mm, and the maximum flow rate is 60ml/min.

◆ Uses AirTAC (Taiwan) filter, pointer gauge shows air pressure, all spray system pipes are acid and alkali resistant corrosion protection pipes.

◆ Spraying system adopts scanning spraying method, limit switch and entry eyesight are combined to control, and PCB is automatically detected by inductive spraying according to the speed and width of PCB, so that the wetting range of flux can achieve the best effect. Inlet spray head and stepping motor are efficient, stable and reliable.

◆ Stainless steel bent forming tray is used underneath the spray head for loading wastewater and flux, which can be extracted and cleaned at will.

◆ The air extraction system is a superimposed automatic recovery system with three layers of stainless steel wire mesh filtration to minimize residual flux blockage in the air extraction pipeline by utilizing the fluid characteristics to filter excess flux.

◆ Pneumatic air knife, which blows excess flux during spraying into the recovery tank to prevent flux from entering the preheating zone and ensure production safety.

◆ All stainless steel + aluminium alloy support, easy cleaning and maintenance, strong corrosion resistance, durable.

Welding System

1. 4mm SUS316L Imported stainless steel furnace liner, new design of furnace liner, beautiful appearance, easy to clean, cast iron heating plate, furnace liner is not deformed

2. Disturbance wave crest, guided jet, the best soldering of SMD components, the wave crest is as smooth as a mirror

3. The width of the wave peak is adjustable to minimize the amount of tin oxidation, and the filter can be drawn out without disassembling the nozzle

4. Increase the anti-oxidation cover at the position of the impeller shaft to reduce the amount of tin oxidation caused by the rotation of the impeller shaft

5. The impeller shaft and wave motor can be disassembled separately without disassembling the tin channel (other brands of wave soldering cannot do this design)

Transport System

Pure aluminum material automatic feeding and connecting device, smooth and stable feeding, great adjustability

The guide rail has its own tilt angle device, which can accurately monitor the tilt angle and control the quality of the board

Titanium alloy claw hooks ensure that the tin will never be stained, and the three-stage fixed guide rails ensure that the guide rails will never be flared, which effectively prevents the guide rails from falling off and jamming.

◆The 4mm copper bead makes the transportation process smooth and stable. (Most other brands use stainless steel layering, which cannot guarantee the smooth transportation for a long time.)

The simplified operating system is convenient for employees to operate, and the PC+PLC control system makes the temperature control accuracy more accurate and stable

The electrical materials are all well-known brands at home and abroad, and the original Siemens PLC ensures that the system is safer and more stable

Temperature control adopts self-tuning PID control algorithm, no need to manually set PID parameters, high control accuracy

Technical parameters

| Model | CY-350B/T | CY-450B/T |

| Heating area number | Stepping motor or rodless cylinder | |

| Number of cooling zone | 6 LITRES | |

| Air pressure of flux | 3-5BAR | |

| Preheating Mode | Mild hot air/infrared | |

| Preheating Zone Number | 4 section | |

| Preheating Lenghth | 1800mm | |

| Warm-up Time | Approx.15min | |

| PCB maximum width | 350mm | 450mm |

| Guide the wide range | 50-350mm | 50-450mm |

| Conveyor Speed | 0-2000mm/min | |

| Conveyor Height | 750±20mm | |

| Transport direction | L→R(R→L) | |

| Transmission way | 4-7° | |

| Solder temperature | 9KW(Room temperature-300℃) | |

| Solder capacity | 400Kg | 500Kg |

| Control method | Brand Computer(Windowsoperating system)+Siemens PLC | |

| Conveyor speed | 3∮ AC380V 90W,Brand: Tai Chuang | |

| Wave motor | 3∮ AC220V 360W*2pcs,Brand: Tai Chuang | |

| Finger cleaning pump | 1P AC220V 10W | |

| Fingers | Special titanium alloy double groove claw | |

| Cooling system | Forced air cooling | |

| The power supply | 5-wire 3-phase 380V 50/60Hz | |

| Start the power | 38Kw | |

| Normal operating power | Approx10Kw | |

| Temperature control mode | Full computer PID closed loop control, SSR drive | |

| Abnormal alarm | Abnormal temperature (super high or super low after constant temperature) | |

| Three color light | Three-color signal light: yellow-heating; green-constant temperature; red-abnormal | |

| Weight | Approx.1800Kg | Approx.2000Kg |

| Installationdimension(mm) | L4300×W1530×H1700mm | |

| Exhaust air requirements | 10 cube /min 2 aisle∮200mm | |

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Professional China frameless stencil printer - Lead-free Wave Soldering machine CY-350B/350T – Chengyuan , The product will supply to all over the world, such as: Dubai, Lithuania, Mexico, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!