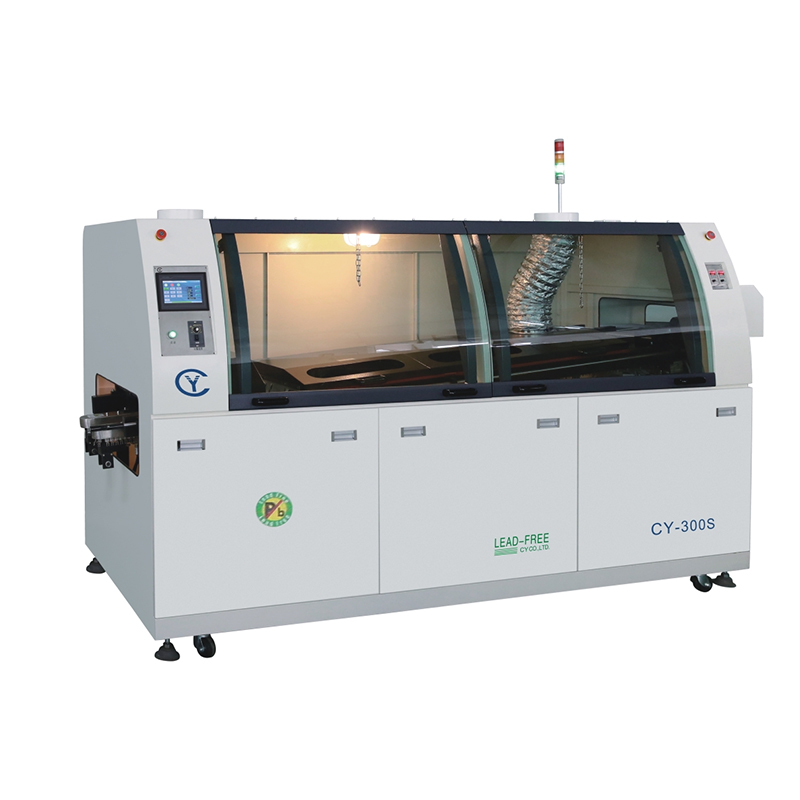

Reasonable price electronics production machinery - Lead-free Wave Soldering machine CY-300S – Chengyuan Detail:

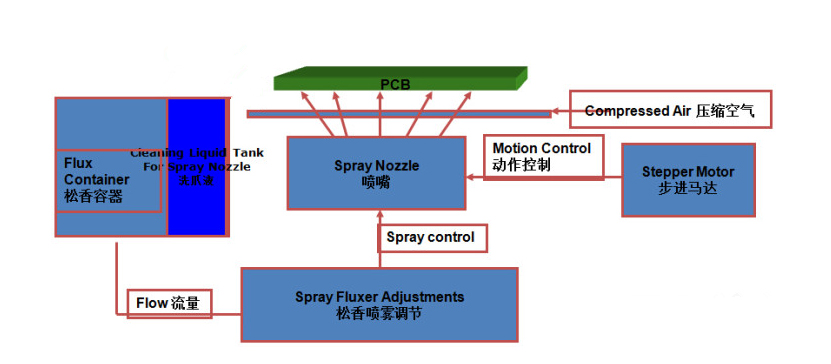

With Lumina (Japan) nozzle, adjustable nozzle height 50-80mm with 20-65mm spray range and maximum flow rate 60ml/min

Use Adeke (Taiwan) filter, pointer gauge shows air pressure, all spray system trachea are acid and alkali resistant anti-corrosion trachea

The spray system uses a scanning spray mode, which is controlled by a combination of a limit switch and an entry glare. The inductive spray is automatically detected on the PCB board according to the speed and width of the PCB board. Making the wetting range of flux reach the best effect, the imported nozzle and stepping motor are efficient, stable and reliable

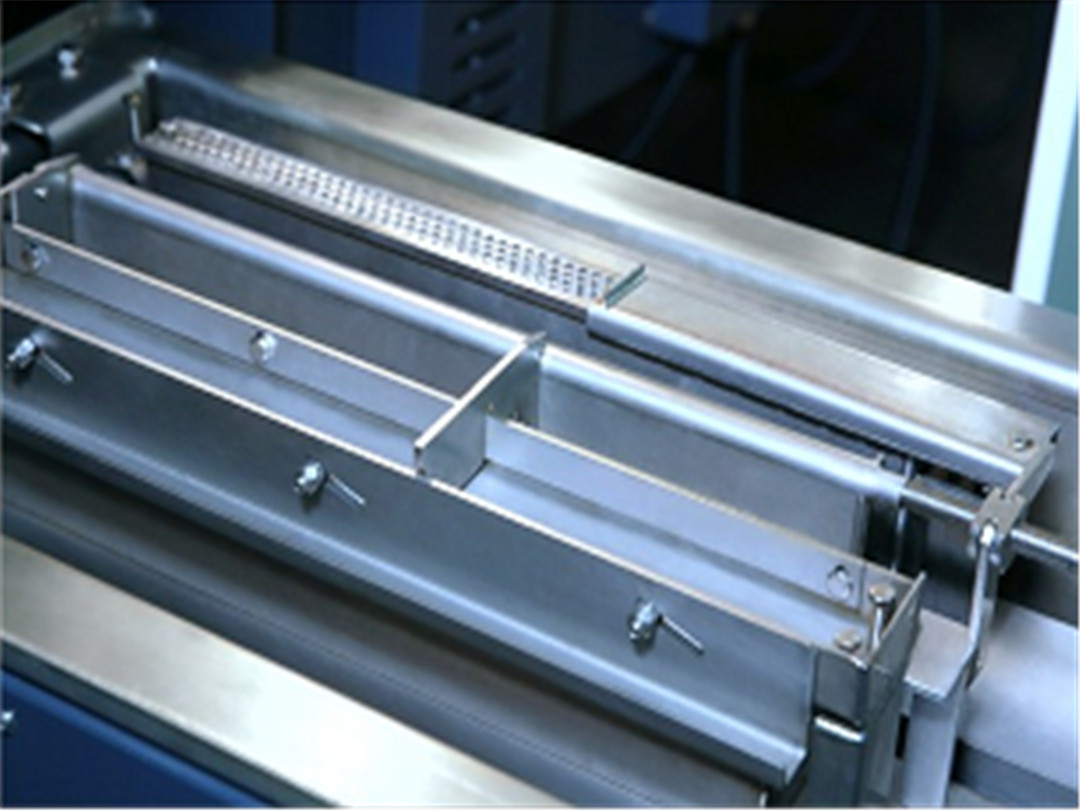

The stainless steel bent-shaped tray under the nozzle is used to load waste water and flux, and can be freely pumped out for cleaning.

The exhaust system is an overlapping automatic recovery system, with three layers of stainless steel wire mesh filtration, which uses the fluid characteristics to maximize the filtration of excess flux and reduce residual blockage of flux in the exhaust pipe

Pneumatic air knife blows excess flux during spraying into the recycling box to prevent flux from entering the preheating zone and ensure safe production

Full stainless steel structure + aluminium alloy bracket, easy to clean and maintain, strong corrosion resistance, durable

4mm SUS316L imported stainless steel bladder, new bladder design, beautiful appearance, easy cleaning, cast iron heating plate, bladder does not distort

Disturbance peaks, guided jets, SMD components are best welded, with smooth peaks like mirrors

Tin slag oxidation: The amount of tin slag produced in 10 hours is 3KG, calculated at 300pcs per hour with PCB board 200*200mm as test plate

Technical parameters

| Model | CY-300S |

| Control mode | Touch screen + PLC |

| Transport motor | 1P AC220V 60W |

| PCB width | 50-300mm(w) |

| Preheating zone | Power: 9KW Length: (1200mm section infrared preheating PID control) |

| Solder Box heating | 9KW (room temperature – 300 C) |

| Solder box capacity | 300Kg |

| Wave motor | 3P AC 220V 0.37KW*2pcs,Brand:Tai Chuang(Taiwan) |

| Pawl wash pump | 1P AC220V 6W |

| Cooling | Normal air cooling |

| PCB Transport Direction | L→R /(R→L) |

| Nozzle movement | Stepper motor |

| Scaling powder | 6 LITRES |

| Flux pressure | 3-5BAR |

| Welding angle | 4-7℃ |

| Power supply | 3P AC380V 50Hz |

| Total power/operating | 18KW4KW |

| Weight | 1100KG |

| Body dimensions | 2800(L)x1200(W)x1700mm(H) |

| Exterior dimensions | 3550(L)x1200(W)x1700mm(H) |

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Reasonable price electronics production machinery - Lead-free Wave Soldering machine CY-300S – Chengyuan , The product will supply to all over the world, such as: Turkmenistan, Holland, Cyprus, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.