02

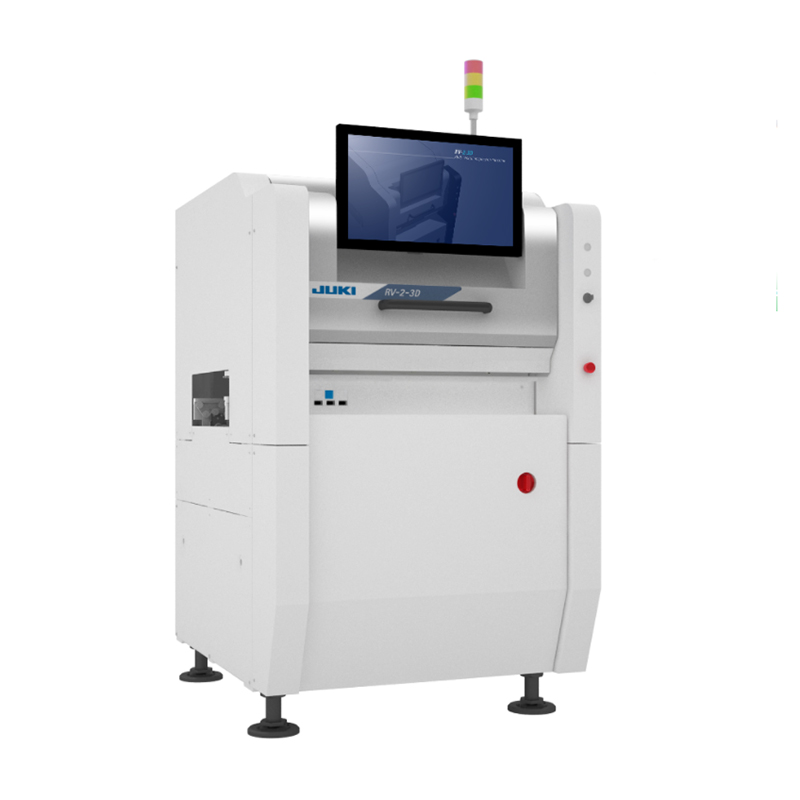

The world’s fastest mounting speed in its class!

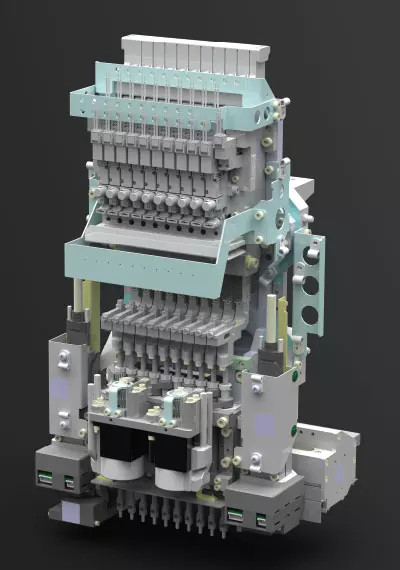

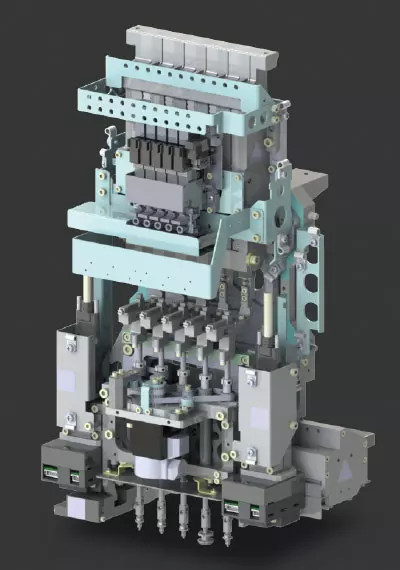

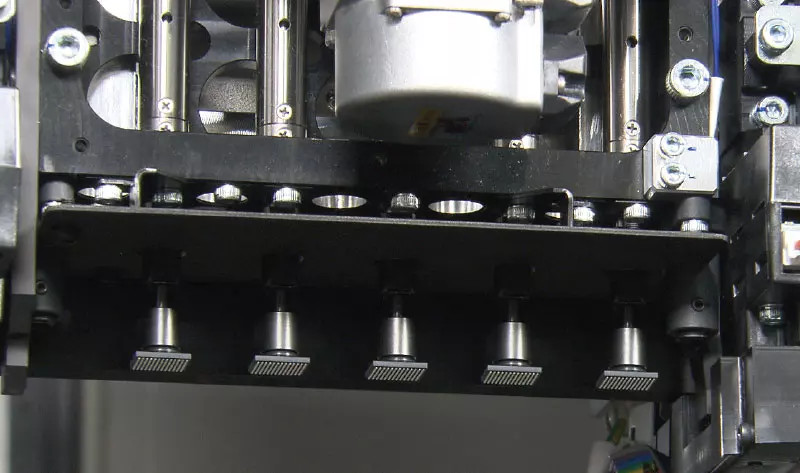

By adopting a new-generation servo system from upper-ranked models and utilizing a lightweight and compact universal type head we have speeded up mounting more than 25% compared to conventional models to achieve the world’s fastest mounting speed in its class of 46,000 CPH (chips per hour).

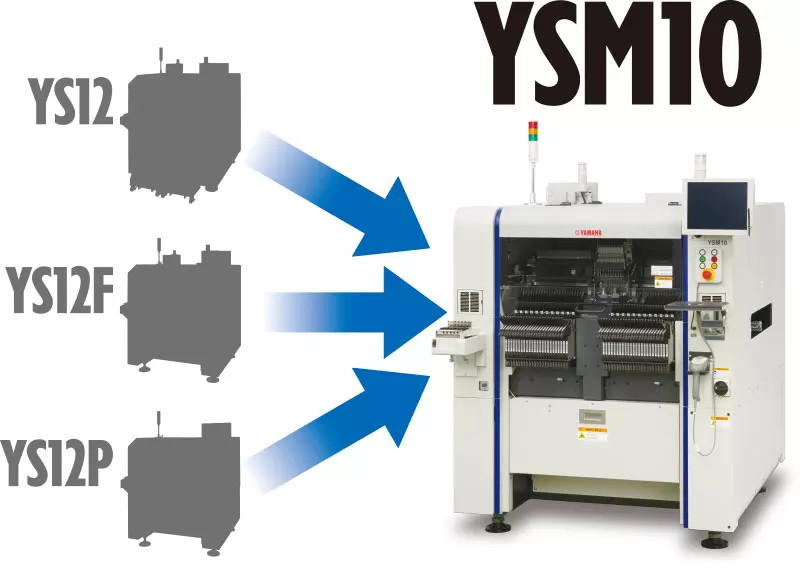

Single Platform

Here, 3 models or namely the YS12 with flexibility and mobility, YS12P with some simpler specifications, and YS12F with superb component handling compatibility are integrated into one type of platform. This is a super-entry model combining high parts compatibility and versatility along with the usual small size body, high speed, and space saving specs.

Specifications:

| Model | YSM10 |

| Applicable PCB | L 510 x W 460mm - L 50 x W 50mm Note : Available in lengths up to L950mm as an option. |

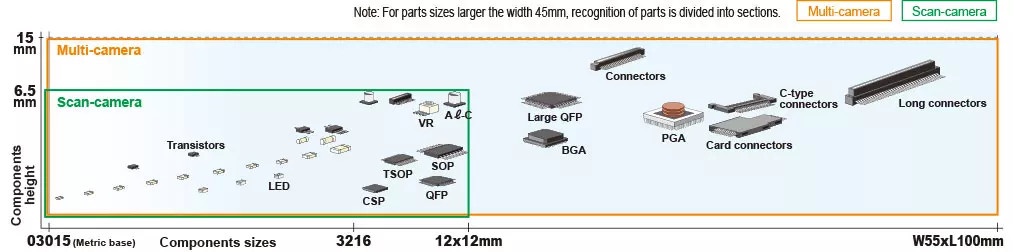

| Applicable components | 03015mm to W55 x L100mm (For parts sizes larger the width 45mm, recognition of parts is divided into sections.), Height 15mm or less Note : A multi camera (option) is required for part heights exceeding 6.5mm or part sizes exceeding 12mm |

| Mounting capability | HM head (10 nozzle) specification : 46,000CPH (under optimum conditions as defined by Yamaha Motor) HM 5 head (5 nozzle) specification : 31,000CPH (under optimum conditions as defined by Yamaha Motor) |

| Mounting accuracy | +/-0.035mm (+/-0.025mm) Cpk 1.0 (3σ) |

| Number of component Types | Fixed plate : Max. 96 types (conversion for 8mm tape feeder) Tray : 15 types (maximum when equipped with sATS15, JEDEC) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L1,254 x W1,440 x H1,445mm |

| Weight | Approx. 1,270kg |